PRO ULTIMATE METALLIC

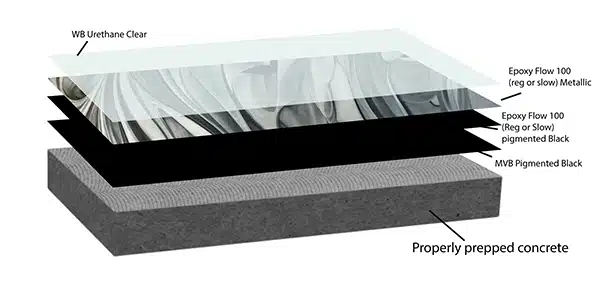

A step up from our basic metallic floor featuring two coats of our popular Epoxy Flow 100. This metallic system adds a clear topcoat of our WB Urethane for extra protection and chemical resistance.

PRO ULTIMATE METALLIC BENEFITS AND CHARACTERISTICS

PRO ULTIMATE METALLIC BENEFITS AND CHARACTERISTICS

Scratch & Scuff Resistant

LOW ODER

LONG WORK TIME

CHEMICAL RESISTANT

INTERIOR

HOT TIRE RESISTANT

CROSS SECTION LAYER

- Basecoat = Poly 90 @ 200 sqft/gallon

- Flake @ 10 sqft/pound (full flake)

- Topcoat = Poly 90 @ 175 sqft/ gallon

Step-by-Step Installation of Pro Ultimate Metallic Coating System

Pre-Application Assessment & Preparation

1. PREP: One of the key components is to ensure that the surface is free from sealers, dirt, oils, glues and other contaminants. It also needs to be profiled.

a. A few methods for properly preparing the concrete are:

i. Using a lower grit (16, 30) metal bond diamond tool on a single headed or planetary grinder with a vacuum and grinding dry. Vac and wipe clean. Note: Dry grinding and creating the proper surface profile (one that mimics a light broom finish on concrete is key)

2. Apply MVB: Mix MVB by drill mixing. Apply MVB to the floor by pouring the Epoxy on the floor and using a notched squeegee to spread the product and immediately backroll with an 18” , ⅜” nap roller cover. .(MVB hangs out better on the floor than in the bucket. Don’t dwell in the bucket as this will expedite the set time) Coverage rates are approximately 50-100 sq ft per gallon.

a. Application Tip: Always ensure the current coating is tack free and within the recoat window before moving onto the next coat. If not, screen and wipe prior to application.

3. Apply Epoxy Flow 100 (reg. Or slow with Black epoxy pigment(or other desired epoxy pigment): Mix the solid color pigment in the “A” Side of the Epoxy Flow 100 for 1-2 minutes using a drill mixer at low speed. After mixing the pigment with the “A” Side mix with part B. Epoxy Flow 100 is to be mixed as 2 parts “A” to 1 part “B”. Always measure A side and B side before mixing. (2A:1B). Mix Epoxy Flow 100 by drill mixing for 2 minutes.. After mixing, immediately pour the product on the floor. (do not let the product dwell in a bucket). Spread by using a notched squeegee and back roll with a roller (18”, ⅜” nap is most typical). Spike shoes are a must to walk through the product. Application rates are typically 100 to 125 sq ft per gallon. Allow to dry tack free before the next coat. Adhere to recoat windows for Flow 100 by referring to the data sheet. Screen the floor with a 120 or coarser sand screen to de-gloss and profile floor if the material goes beyond the recoat window.

4. Apply Epoxy Flow 100(Reg., Slow) with metallic pigment: Mix the metallic pigment in the “A” Side of the Epoxy Flow 100 for 1-2 minutes using a drill mixer at low speed. After mixing the pigment with the “A” Side mix with part B. Epoxy Flow 100 is to be mixed as 2 parts “A” to 1 part “B” Mix Flow 100 by drill mixing for 2 minutes. After mixing, immediately pour the product on the floor. (do not let the product dwell in a bucket). Application rates are typically 50 to 100 sq ft per gallon. For metallics many creative aspects can be achieved by using erratic rolling patterns, using other metallic colors in areas as highlights, and misting solvents such as xylene on the floor. Testing these techniques is recommended before doing the floor. Reference what others have done on youtube or other sources to learn unlimited techniques and effects. Spike shoes are a must to walk through the product. Adhere to recoat windows for Flow 100 by referring to the data sheet. Screen the floor with a 220 or coarser sand screen to de-gloss and profile floor if the material goes beyond the recoat window prior to applying wb urethane.

5. Apply WB Urethane Gloss or Matte: Mix WB Urethane Gloss/Matte by drill mixing (refer to product data for each products mixing instructions). Apply the product to the floor by pouring in ribbons on the floor and spreading evenly as you go. Do not allow it to sit on the floor very long before rolling. Do not over roll. It is important to get even coverage on the floor to avoid roller marks. This product goes on white and dries clear. Use an 18”, ⅜” nap roller cover. Application rate is around 300-400 sqft per gallon

a. Add traction additive if desired. Our Grip X (100 grit) or Wear Pack (220 grit) are good options. Test and area prior to use to ensure this is the grip size you like

i. Protect area from traffic until the coating has sufficiently dried. Refer to product data sheet on website for dry time estimates

VIDEOS

Coverage rates are averages and can vary by applicator and does not account for waste. Please order extra.