ROOKIE POLY FLAKE

A full flake system with our tried and true 100% solids epoxy, Epoxy Flow 100, as a bascoat and UV stable Poly 90/85 as a topcoat. Creates a thicker, smooth floor.Available in slow set options for extended work times during installation.

ROOKIE POLY FLAKE SYSTEM BENEFITS AND CHARACTERISTICS

ROOKIE POLY FLAKE SYSTEM BENEFITS AND CHARACTERISTICS

SCRATCH & SCUFF RESISTANT

LOW ODER

LONG WORK TIME

CHEMICAL RESISTANT

INTERIOR

HOT TIRE RESISTANT

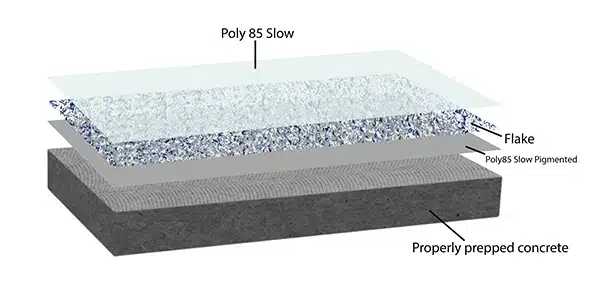

CROSS SECTION LAYER

- Basecoat = Poly 90 @ 200 sqft/gallon

- Flake @ 10 sqft/pound (full flake)

- Topcoat = Poly 90 @ 175 sqft/ gallon

Step-by-Step Installation of Rookie Poly Flake System

Pre-Application Assessment & Preparation

1. PREP: One of the key components is to ensure that the surface is free from sealers, dirt, oils, glues, and other contaminants. It also needs a profile.

- Do all repairs before grinding so repairs are ground flush with the floor. We recommend our Instant Medic Hard for all repairs for this coating system.

- Methods for properly preparing the concrete are:

- Using a lower grit (16, 30) metal bond diamond tool on a single headed or planetary grinder with a vacuum and grinding dry

a. Vacuum floor clean. Remove any other residual dust by leaf blowing and/or microfiber wiping. Do not use water

b. You are going for a floor with a light broom finish like profile that is completely profiled, bone dry, and free of contaminants

2. Apply Pigmented Poly 85 Slow: Drill mix Poly 85 Slow. Mix in the proper amount of pigment (1 pigment/4 gallons on Poly 85 Slow). Apply Poly 85 Slow to the floor by dipping and rolling out of a pan. Use an 18”, ⅜” nap roller cover. Larger floors can be accomplished by pouring the Poly on the floor and using a flat squeegee to spread the product and immediately backrolling. Coverage rates for dipping and rolling are approximately 250 sq ft per gallon. *Poly 85 Slow has a long pot life (can hang out in a bucket or pan) for up to 45 minutes. Once applied to the floor there is up to a 45 minute work time to roll it out and another 45 minutes or more to broadcast chips to the area. Smaller floors such as a garage are best accomplished by rolling and broadcasting your way out of an area. Spike shoes are extremely important for broadcasting and double checking your work. Refer to data sheet for more information.

3. Broadcast Flake:Top Coat – Poly 85 Slow Clear: After the base coat with flakes has sufficiently set and is no longer tack free (typically 9-12 hours. This is greatly affected by temperature) scrap the floor by using a straight edge or use a sand screen to knock down jagged flakes. Vacuum and blow the floor clean. Apply a clear top coat of Poly 85 Slow by pouring a bead of Poly 85 Slow on the floor and using a flat squeegee to spread the product. Immediately backroll with an 18”, ⅜” nap roller (coverage is approximately 175 sqft/gallon). Spike shoes are necessary to walk through the floor when using a squeegee. Be sure and get 100 percent coverage when squeeging or dry spots can occur.

a. Add traction additive if desired.

b. Protect area from traffic until the coating has sufficiently dried (refer to tech data for dry times)

VIDEOS

Please Read: We do not sell the ‘finished floor’. You are responsible for creating the finished product. Please contact us with any questions. Mock ups are encouraged before doing your project. The information supplied by Concrete Floor Supply about our products and uses is not a representation or a warranty. It is supplied on the condition that you will make your own tests to determine the suitability of the product for your own particular purpose. Any use or application is the sole responsibility of the user. Listed physical properties are typical and should not be construed as specifications